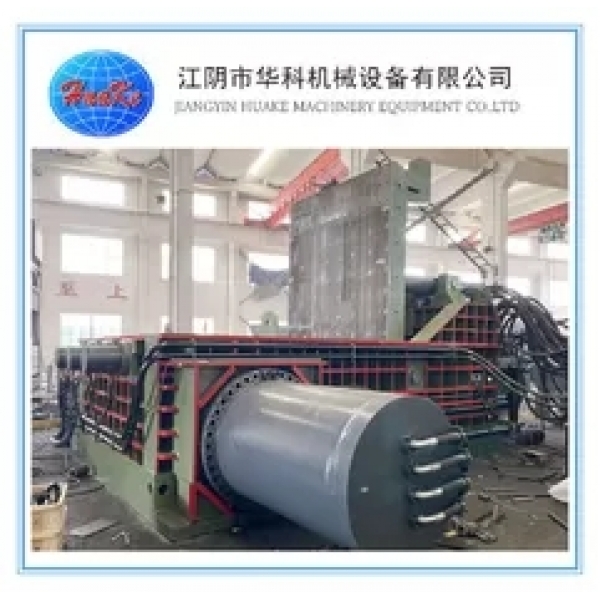

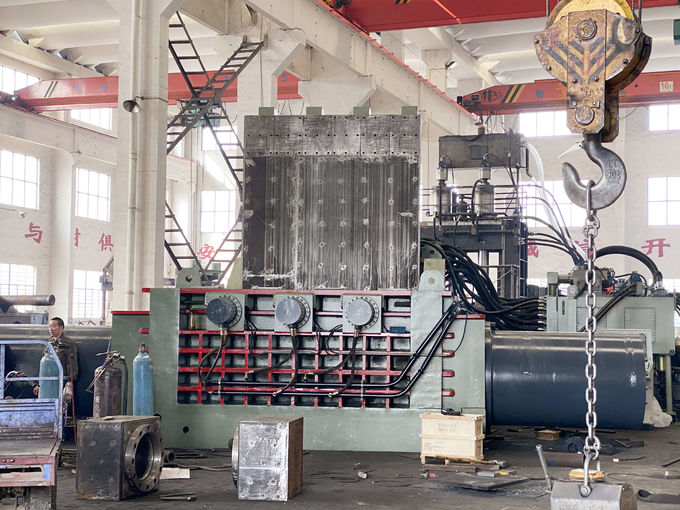

Y81-1000 Hydraulic Scrap Baling Press Machine 1000 Ton

- Product Details:

Place of Origin: china

Brand Name: HUAKE

Certification: CE SGS

Model Number: Y81-1000

Payment & Shipping Terms:

Minimum Order Quantity: 1 SET

Price: 10000-150000 USD

Packaging Details: EXPORT WORTHY PACKAGE

Delivery Time: 60 DAYS

Payment Terms: L/C, T/T, D/P, Western Union

Supply Ability: 50 PCS/Year.

- Order phone:+86-13003381217

- Inquiry

Detail

| Model NO.: | Y81-1000 | Advantage: | High Productoon Rate, Very Tight Bale, Can Bale Heavy Materials |

| Other Name: | Scrap Metal Compactor/hydraulic Metal Baler/steel Baler Machines | Origin: | China |

| HS Code: | 84629190 | Port: | Shanghai, China |

| Control Type: | PLC | Customized: | Customized |

| Condition: | New | Automatic Grade: | Automatic |

| Certification: | CE | Fit For: | Large Recycler Plant .,steel Plant |

| High Light: | 1000T hydraulic scrap baling press machine , CE 1000T hydraulic scrap baling press machine , Y81-1000 hydraulic metal baler | ||

China Y81-1000 tons Force Scrap & Recycling Hydraulic Metal Baler for Hot Sale

detailed specs to choose from :

Y81-1000 high density Hydraulic Scrap Steel Baler 1000 tons power / automatic heavy duty baling machine

MAIN PARAMETERS FOR Y81-10000 HYDRAULIC SCRAP METAL BALER MACHINE 1000 TONS POWER Machine vedio: https://youtu.be/Q0JZ7iJawm |

|||||||

| ITEM | PARAMETERS | REMARKS | |||||

| 1 | MAIN CYLINDER | MODEL | YG700/500-1150 | TRAVEL LENGTH | 1150mm | 1000*2 TONS POWER | |

| MAXIMUM THRUST | 10000 KN | QUANTITY | 2 | ||||

| 2 | SIDE CYLINDER | MODEL | YG400/310-2750 | TRAVEL LENGTH | 2750mm | 335TONSx3=1005TONS POWER 335x3= 1005 TONS POWER |

|

| MAXIMUM THRUST | 3350 KNX3 | QUANTITY | 3 | ||||

| 3 |

COVER DOOR CYLINDER |

MODEL | YG280/200-2600 | TRAVEL LENGTH | 2600mm | 160TONSx2=320 TONS POWER | |

| MAXIMUM THRUST | 1600 KNX2 | QUANTITY | 2 | ||||

| 4 | DOOR LOCK CYLINDER | MODEL | YG200/120-70 | TRAVEL LENGTH | 70mm | 100TONS X3=300 TONS POWER | |

| MAXIMUM THRUST | 1000 KNX3 | QUANTITY | 3 | ||||

| 4 | PRESS BOX SIZE | 3500×3000×1400 mm | L×W×H | ||||

| 5 | BALE SIZE (700~2500)×700x700MM | 700x700MM | L×W×H | ||||

| 6 | BALE DENSITY | ≥2000kg/m3 | STEEL | ||||

| 7 | HYDRAULIC SYSTEM WORKING PRESSURE | ≤25 MPa | |||||

| 8 | TOTAL POWER OF MACHINE | 225kW | |||||

| 9 | SIGNLE CYCLE TIME | 180SECONDS | EMPTY LOAD | ||||

| 10 | POWER SPECFICATION | 380 V/3P,50 Hz | |||||

| 11 | OPERATION MODE | AUTOMATIC PLC WITH REMOTE CONTROL GRAPLE TO GET THE BALE OUT |

|||||

| 12 | MOTOR FOR THE MAIN PUMPS | MODEL | YX3-225-4 | RATED POWER | 45KW | ||

| NOMINAL TURNING SPEED | 1470 r/min | Quantity | 5 Sets | ||||

| 13 | Hydraulic Pump | Model | A4V-250 | Rated Pressure | 31.5MPa | ||

Nominal Displacement |

250 ml/r | Quantity | 5sets | ||||

| 14 | Oil cooler | Model | B-14 | COOLING EFFFECT | 32SQURE METERS | ||

| TYPE | Finned heat exchanger | Quantity | 1set | ||||

| 15 | oiL TANK SIZE | 8000liters (hydraulic7500liters ) | Buyer prepare | ||||

| 16 | machine size | 9792×8796×3185(cover door open 5378)mm | L×W×H | ||||

| 17 | Floor space | 10.6 ×11.5 m | |||||

| 18 | MACHINE WEIGHT: | 138.5TONS

|

|||||

METAL BALER CHARACTERISTIC

1. The hydraulic driving is adopted for the machine

2. The manual or PLC automatic control operations.

3. Installation does not need the foundation screw

4. Can choose diesel engine drive or motor driv

5. Three out- bag ways: Turn, Side push, front push.

6. The chamber box size and bale size can according to the customer request.

7, Voltage/frequency can according to customer requirement.

8, Can add two sides of knives and teeth on the chamber box

9. Can be equipped with cooler or heater

Watch The Video

Machine vedio: https://youtu.be/Q0JZ7iJawmY

Place of Origin: Jiangsu, China (Mainland)

Brand Name: Huake

Service : the machine are always tested and assembled before shipping,customer only need to follow simple steps to start .Engineers available on phone 24 hours ,unsolvable problem come to fix.

Model Number: Y81F-160QF

Condition: New

Color: User Defined

Packaging & Delivery

Features:

A) Hydraulic drive, manual valve operation or PLC control...

B) Bale-discharging: "turn-out", "push-out", "forward-out" & manual discharging.

C) Options for different force, press box size, bale shape & size

D)Electrical motor, diesel engine or generator for power.

Applications:

Y81 series of hydraulic scrap balers are applied in steel mills, recycling plants, ferrous & non

-ferrous smelting industry to press scrap metal (steel, copper, aluminum, stainless steel, discarded automobiles, etc)

Into acceptable furnace charges in shape of cuboids, cylinders & octagons. Pre Sales Service

1. Assist the buyer to do a good job in demand planning and analysis, and cooperate with the design department to formulate a complete plan based on the actual situation.

2. Closely cooperate with the buyer and fully consider the user's use function.

3. Provide professional technical consulting services.

4. Provide visit reception and various convenient conditions at any time.

Service In Sale

1. Make planned sales contract and technical agreement.

2. After the contract comes into effect, provide the list of design, manufacture, installation, commissioning, operation and maintenance of the contract equipment to the customer in the shortest time.

3. In technical design, we will optimize the design and keep improving.

4. In the manufacturing process, we will fully cooperate to arrange drawing review, product supervision, inspection and acceptance.

5. Product manufacturing, material and product debugging and inspection shall comply with the requirements of relevant standards, and do a good job in routine item inspection, manual operation test, electrical action test, protection circuit test, etc. The parts and framework of the product shall be manufactured in strict accordance with the relevant process rules. The welding shall be even, continuous, free of false welding and missing welding, and free of welding penetration, crack, undercut, slag splashing and air hole. All welding parts must be inspected one by one. The overall dimensions of parts must meet the requirements of drawings.

6. The factory shall complete all manufacturing and inspection of the contract equipment before leaving the factory. The main contents of delivery acceptance include the witness of equipment performance test before delivery, the inspection of the integrity of the supply of traveling equipment and its accessories, spare parts, the inspection of the appearance and size of equipment, the size of installation interface, etc.

7. After the contract equipment passes the factory acceptance, the factory shall pack according to the packaging requirements of the contract and take protective measures.

After Sales Service

Within the specified warranty period, our factory is responsible for repairing or replacing the products free of charge. After the expiration of the warranty period, we promise to provide lifelong maintenance for the equipment, regularly organize after-sales service personnel, conduct patrol visits, understand the use and maintenance of the products, and maintain the equipment. After receiving the information of the buyer's questions, our factory will reply within 1 hour, so that the user is not satisfied with the quality and the service will not stop.

Our factory establishes user account for all users, and will issue customer satisfaction rate questionnaire to users every year to investigate the use and quality of our products. Users can timely feed back their satisfaction or experience to our factory through customer satisfaction rate questionnaire. In addition, users can also timely transmit their opinions and improvement problems to our factory through the product user service processing sheet carried by our factory's service personnel. We solemnly promise not only to provide the buyer with qualified new products, but also to provide high-quality services. We will establish a convenient and quick contact service channel between the buyer and the seller, and run the after-sales service, advanced service, whole process service and life-long service throughout the whole process of the product life cycle.