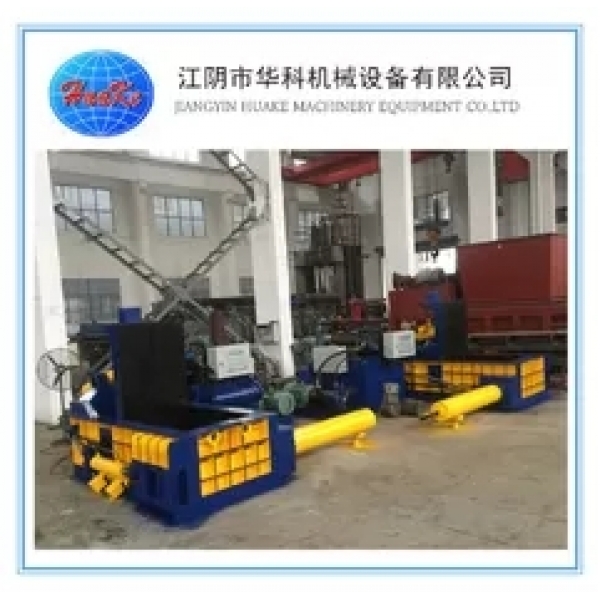

OEM Hydraulic Scrap Baling Press Machine , Copper Aluminium Iron Recycling Machine

- Product Details:

Place of Origin: china

Brand Name: HUAKE

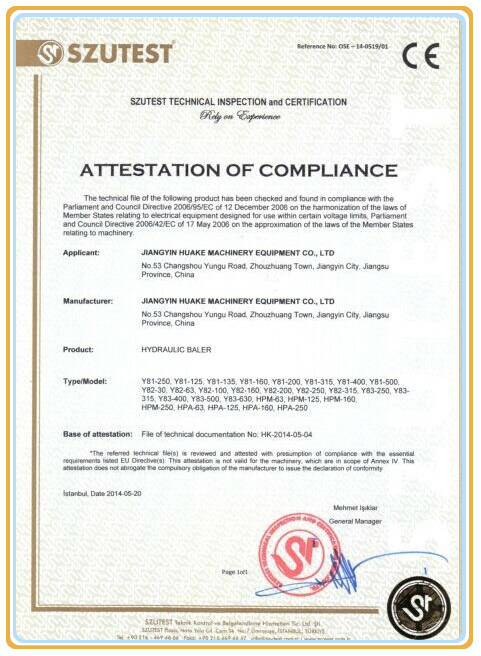

Certification: CE SGS

Model Number: Y81-160

Payment & Shipping Terms:

Minimum Order Quantity: 1 SET

Price: 8000-20000USD

Packaging Details: EXPORT WORTHY PACKAGE

Delivery Time: 35-40 DAYS

Payment Terms: L/C, T/T

Supply Ability: 200PCS Per Year

- Order phone:+86-13003381217

- Inquiry

Detail

| Other Name: | Aluminum Steel Iron Shavings Metal Baler For Recycling | Bale Discharge Ways: | 3 Ways Choosable : Side Push Out,turn Out,front Push Out |

| Operation Ways: | PLC Automatic .remote Control | Transport Package: | Nude Packing, Load Container Directly |

| Specification: | CE SGS | Trademark: | HUAKE |

| Origin: | Jiangsu China | Power Source:: | Hydraulic |

| High Light: | OEM hydraulic scrap baling press machine , Y81-160 hydraulic scrap baling press machine , 160T iron recycling machine | ||

Hydraulic Compress Scrap Aluminum Iron Copper Metal Baler For Recycling Business

| technical specification | |||||

| Model | Main Cyl.Force(ton) | Press Box Size(mm) | Bale Size(mm) | Bale Weight(kg) | Motor(KW) |

| Y81F-125 | 125 | 1200*700*600 | 300*300 | 50-70 | 15 |

| Y81F-160 | 160 | 1600*1000*800 | 400*400 | 100-150 | 22 |

| Y81F-200 | 200 | 1600*1200*800 | 400*400 | 120-220 | 37 |

| Y81F-250 | 250 | 2000*1750*1200 | 500*500 | 300-500 | 60 |

| Y81F-315 | 315 | 3000*2500*1200 | 600*600 | 400-700 | 90 |

| Y81F-315 | 315 | 3500*3000*1300 | 700*700 | 600-1000 | 90 |

| Y81K-315 | 315 | 4000*3000*1300 | 700*700 | 800-1200 | 135 |

| Y81F-400 | 400 | 3500*3000*1300 | 700*700 | 800-1300 | 135 |

| Y81K-400 | 400 | 4000*3000*1300 | 700*700 | 900-1300 | 135 |

| Y81F-500 | 500 | 4000*3000*1300 | 700*700 | 900-1500 | 135 |

| Y81K-500 | 500 | 4000*3500*1300 | 700*700 | 900-1600 | 135 |

| Y81F-600 | 600 | 4000*3000*1400 | 700*700 | 1000-1700 | 180 |

| Y81K-600 | 600 | 4000*3000*1300 | 700*700 | 1100-1700 | 180 |

| Y81F-800 | 800 | 4000*3500*1400 | 700*700 | 1200-1800 | 180 |

| Y81K-800 | 800 | 4000*3500*1400 | 700*700 | 1200-1800 | 180 |

| Y81F-1000 | 1000 | 5000*3500*1500 | 700*700 | 1300-1900 | 225 |

| Y81K-1200 | 1200 | 5000*3500*1500 | 700*700 | 1400-2000 | 270 |

Aluminum Steel Iron Shavings Metal Baler for Recycling

INTRODUCTION :

Aluminum Steel Iron Shavings Metal Baler for Recycling can squeeze all kinds of scrap metal raw materials into cuboid, cylinder and other various shapes, its compression ratio is high, convenient for storage, transportation and smelting, improve the furnace feeding efficiency, suitable for scrap steel processing and distribution center, scrap car dismantling center, casting industry, steel mills and non-ferrous metal industry.

1) Hydraulic drive,manual or PLC control.

2) Bale-discharging:"turn-out","push-out","forward-out" .

3) No footing bolts needed in installation;diesel engine can be power.

4) Spare parts: supply one set of spare parts for free, tool box, operation book.

Aluminum Steel Iron Shavings Metal Baler for Recycling is used to crush, cut and bale a wide range of scrap metal. They could deal efficiently and quickly with metals scraps, whether it’s something as small as Cans, Aluminium and steel turnings and Wire scrap, or as large and robust as steel sheet, washing machines, other white goods and whole Vehicles. Choose a metal automatic baler from Ecohydraulic and benefit from a reliable and fit-for-purpose solution for your recycling needs.

1) All structural parts are reliable and stable. The wear-resistant plate is made of Hardox plate imported from Switzerland, featuring long service life and low maintenance cost;

2) The operation mode can be manual mode or automatic control mode, which is simple and easy to learn;

3) Bale delivery methods include automatic bale turning out, pushing bale out, picking bale out by steel grasping machine, etc.;

4) All models are hydraulic drive.

SPECIFICATIONS TO CHOOSDE FROM

Introduction

Place of Origin: Jiangsu, China (Mainland)

Brand Name: Huake

Service : the machine are always tested and assembled before shipping,customer only need to follow simple steps to start .Engineers available on phone 24 hours ,unsolvable problem come to fix.

Model Number: Y81-160

Condition: New

After-sales Service Provided: Engineers available to service machinery overseas

Color: User Defined

Packaging & Delivery

Packaging Detail: Nude packing, loading container directly.

Delivery Detail: 15-20 days

Features:

A) Hydraulic drive, manual valve operation or PLC control...

B) Bale-discharging: "turn-out", "push-out", "forward-out" & manual discharging.

C) Options for different force, press box size, bale shape & size

D) Electrical motor, diesel engine or generator for power.

Applications:

Y81 series of hydraulic scrap balers are applied in steel mills, recycling plants, ferrous & non

-ferrous smelting industry to press scrap metal (steel, copper, aluminum, stainless steel, discarded automobiles, etc)

Into acceptable furnace charges in shape of cuboids, cylinders & octagons.

Watch The Video

Youtube:www.youtube.com/watch?v=QHD1xZvVTQY

we update often machine vedios please follow us on youtube , thanks

Pre Sales Service1. Assist the buyer to do a good job in demand planning and analysis, and cooperate with the design department to formulate a complete plan based on the actual situation.

2. Closely cooperate with the buyer and fully consider the user's use function.

3. Provide professional technical consulting services.

4. Provide visit reception and various convenient conditions at any time.

Service In Sale

1. Make planned sales contract and technical agreement.

2. After the contract comes into effect, provide the list of design, manufacture, installation, commissioning, operation and maintenance of the contract equipment to the customer in the shortest time.

3. In technical design, we will optimize the design and keep improving.

4. In the manufacturing process, we will fully cooperate to arrange drawing review, product supervision, inspection and acceptance.

5. Product manufacturing, material and product debugging and inspection shall comply with the requirements of relevant standards, and do a good job in routine item inspection, manual operation test, electrical action test, protection circuit test, etc. The parts and framework of the product shall be manufactured in strict accordance with the relevant process rules. The welding shall be even, continuous, free of false welding and missing welding, and free of welding penetration, crack, undercut, slag splashing and air hole. All welding parts must be inspected one by one. The overall dimensions of parts must meet the requirements of drawings.

6. The factory shall complete all manufacturing and inspection of the contract equipment before leaving the factory. The main contents of delivery acceptance include the witness of equipment performance test before delivery, the inspection of the integrity of the supply of traveling equipment and its accessories, spare parts, the inspection of the appearance and size of equipment, the size of installation interface, etc.

7. After the contract equipment passes the factory acceptance, the factory shall pack according to the packaging requirements of the contract and take protective measures.

After Sales Service

Within the specified warranty period, our factory is responsible for repairing or replacing the products free of charge. After the expiration of the warranty period, we promise to provide lifelong maintenance for the equipment, regularly organize after-sales service personnel, conduct patrol visits, understand the use and maintenance of the products, and maintain the equipment. After receiving the information of the buyer's questions, our factory will reply within 1 hour, so that the user is not satisfied with the quality and the service will not stop.

Our factory establishes user account for all users, and will issue customer satisfaction rate questionnaire to users every year to investigate the use and quality of our products. Users can timely feed back their satisfaction or experience to our factory through customer satisfaction rate questionnaire. In addition, users can also timely transmit their opinions and improvement problems to our factory through the product user service processing sheet carried by our factory's service personnel. We solemnly promise not only to provide the buyer with qualified new products, but also to provide high-quality services. We will establish a convenient and quick contact service channel between the buyer and the seller, and run the after-sales service, advanced service, whole process service and life-long service throughout the whole process of the product life cycle.